The Working Principle of the Pellet Briquetting Machine

The working principle of the roller press machine is to compress and shape coal into uniform briquettes. The two main rollers are the most important parts of the machine. The working principle revolves around the utilization of two counter-rotating rollers that exert pressure on the charcoal powder. As the coal material passes between the rollers, it undergoes compression, compacting it into a denser and more cohesive form. The adjustable pressure settings on the rollers allow for precise control over the density and shape of the produced briquettes.

The Working Process of the Double Roller Press Machine

For the working process, it can be divided into three parts. The first phase is the preparation. The pellet press machine can have a better performance on the charcoal powder. Therefore the raw materials should conduct some procedures before the forming stage. When the carbonized materials get out of the carbonization furnace, the materials become charcoal bulk. The original shape is difficult to process, so the outcomes need to get into the grinding machine to refine. While in the grinding machine, the charcoal bulk gets into powder condition.

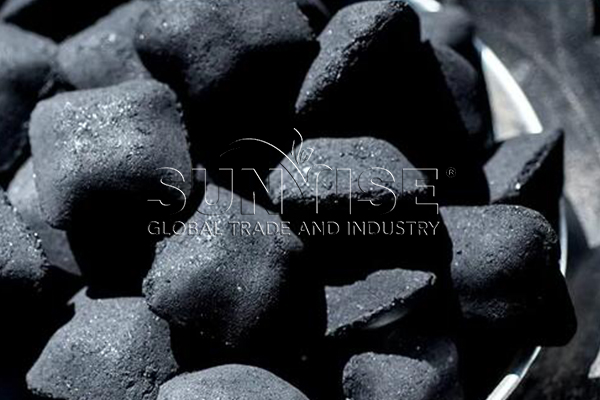

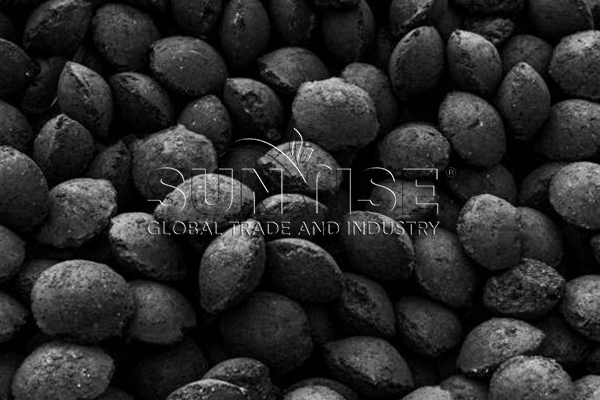

By the time of roller press machine starts to work, the charcoal powder fills in the inlet of the machine to process into the charcoal pellet. The two main rollers are working at the same time. In that case, the charcoal powder falls in the gap between the rollers. As a result, the charcoal briquettes come out of the outlet of the machine.

Last but not least, the charcoal pellets can be sold in their original status or packed as a formal commodity to increase their value. The customer can choose to use the packing machine or not. The packaging of plastic bags is a good promotion way as well. For one thing, the print of the packing bag is the first thing that the customers would notice. So it is very important to leave a perfect impression on the customers. For another, the high quality of the charcoal products can attract returned customers. The design of the packing bag can keep more regular customers.

The Benefits of the Pellet Press Machine

The working principle of charcoal double roller press machines is centered around compression, mixing, and regulation to produce uniform and high-quality coal briquettes. By understanding how these machines operate, charcoal producers can constantly optimize production processes, enhance the quality of their briquettes, and improve overall efficiency. Investing in charcoal double roller press machines is a strategic choice for coal manufacturers looking to streamline their operations and meet the demand for sustainable and efficient charcoal briquette production.

All in all, the working process of the pellet press machine is easy to operate. Due to the simple structure, the roller press machine is also an equipment that is easy to maintain. All these features can be beneficial for the business owner to produce regular and high-quality charcoal pellets.