In the processing line of carbonization, people always focus on the reacting furnace, however, the charcoal press machine is something that needs more attention. The shisha charcoal press machine contains several functional parts to reach the goal of production. With the rather simple working principle, the machine is easy for the worker to operate. The unique traits of the shisha charcoal press machine make the applications of the machine wider. With the development of technology, the producing machines also comply with the improvement.

What components does the shisha charcoal press machine contain?

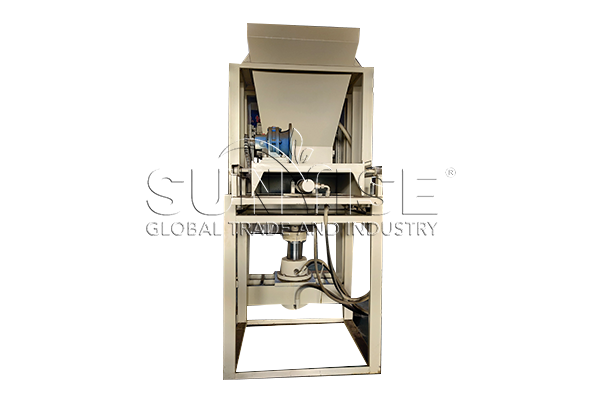

Like other charcoal press machines, the Shisha charcoal press machine uses a high-pressure pressing system to produce the charcoal briquettes. In addition, there are several other working units to maintain the working of the machine.

How does the charcoal press machine work?

To have a better understanding of the working process of the charcoal press machine, people should have a basic knowledge of the working principle of the press machine. The work of the shisha charcoal press machine is on the basis of pressing. The hydraulic system provides enough pressure for the pressing system to complete the briquette process.

The shisha charcoal press machine is an equipment that uses machinery impact to press the powder or granular material into briquettes. When the material gets into the compression chamber, the pressure pushes the upper pressure head to press the material. Then the plastic deformation happens to the material, so the solid briquette is forming in the machine. After pressing, some materials may require for high-temperature processing to further increase its density and strength.

What special features does the shisha charcoal press machine have?

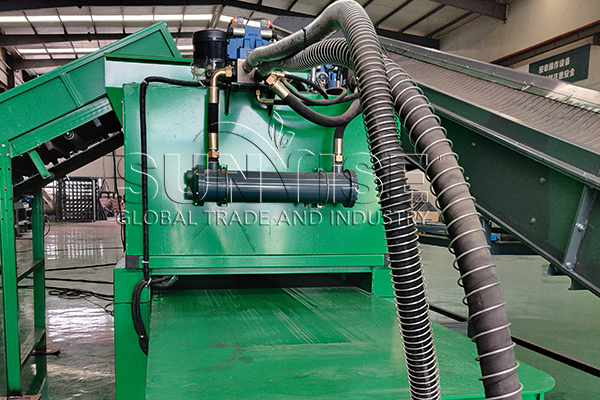

Like other briquette press machines, the shisha charcoal press machine works on the basis of the hydraulic pressing system, but there are still several features that make the machine stand out from the other machines.

What other applications for the shisha charcoal press machine?

The shisha charcoal press machine can conduct many different kinds of powder materials, such as wood powder, bamboo powder, rice husk material, and so on. The press machine can meet the various standards of abundant materials. Therefore, the high precision and high-density pressing that the machine provides is suitable for a lot of fields.

Powder Metallurgy

The charcoal press machine has a wide application in the field of powder metallurgy. The fabrication of metal parts, alloy products, metal ceramics, and other metal powder products can apply the charcoal press machine to shape the material. According to the high-pressure impact, the powder material can get into the shape of a briquette with high strength and density.

Electronic Components

The electronic industry can employ the charcoal press machine to produce the types that they want. In addition, the press machine can press ceramic powder to create electronic ceramics. The electronic resistors, capacitors, and other electronic components are also the outcomes of the machine. The press machine can conduct high-precision pressing for the powder material, satisfying the requirements of shape and size of electronics.

How does the shisha charcoal press machine comply with the trend of development?

With the development of the technology, the customers have a higher standard for the producing machine. Therefore, it is important for the manufacturer to comply with the trend of development. Sunrise Machinery can provide shisha charcoal press machines with the latest technology and standards to the customers.

At the present time, prolonging the use period of fuel is a trending topic for world development. The charcoal powder briquette is one of the great solutions to this problem. If you would like to learn more about this promising industry, please send your inquiry to the following e-mail address. We are looking forward to hearing from you.