The working principle of the double shaft shredder

During the process of production, the pre-processing of the raw materials is the first step. For the raw materials like wood and bamboo, it is necessary for the hard and large materials to get through the crushing machine or the shredder. The most common industrial pulverizer is the double-shaft shredder. Many industries take this machine as a processing machine. As a machine manufacturer, Sunrise Machinery Company can provide high-quality double-shaft shredders and customize them according to the requirements of the customers.

The components of the machine

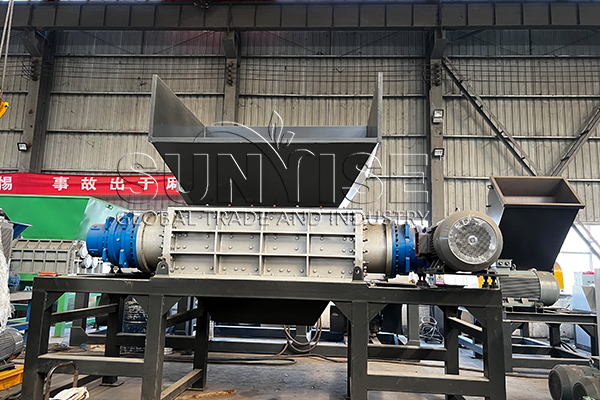

The double shaft shredder is famous for its strong crushing force. Surprisingly, the machine only contains a rather small and simple structure to realize its function. The components of the double shaft shredder are also as simple as they can be.

The first part that the crushing process needs is the feed inlet. The two-shaft shredder is usually equipped with a feed hopper. What’s more, the feed system includes conveyor belts, feeders, and other equipment for feeding materials into the machine for crushing. Usually, the feed hopper is giant to fit the large raw materials.

The second part of the double shaft crushing machine is the double roller. Two main shredders usually have two parallel spines, each of which is equipped with a certain number of blades or tools for crushing materials. The blades are also an important part of treating the raw materials. There are usually different shapes and designs. That is to say, the operator can select the suitable blades according to the characteristics and requirements of the material. Of course, the rotation of two main rollers is driven by the motor. The motor puts the principal axis rotate, and two main rollers start to tear the materials down.

The working principle of double shaft shredder

The working principle of the double shaft crusher is mainly to tear and crush the material using two blades or knives mounted on the rotating spindle in parallel. During the crushing process, there are several steps that the raw materials need to go through.

To start with, the raw materials get into the machine through the feed inlet. Then, the main shafts start to rotate, driving the blades on the shaft to tear the materials apart. Therefore, the materials get into smaller pieces to ease the further treatments and process. After the crushing, it is inevitable that there might be some materials that did not get the thorough process. The operator can collect the larger parts and put them into the shredder machine again to tear them down. At the end of the machine, the outlet may attach to the conveyor belt to get to the next procedure or to the collection container.

Sunrise, the trustworthy manufacturer

The double shaft machine adopts the reverse rotation of the rollers to let the blades crush down the materials. The machine is being widely used because of its high efficiency, uniform particles, and easy operation. As an experienced manufacturer, Sunrise Machinery can provide high-quality and suitable machines for you and the machine can be customized according to the customers. With the source factory, the price of the machine can be the most reasonable in the market. If you are interested in the charcoal materials preparation machine or charcoal production line, please feel free to contact us. Our customer service can offer you the most professional advice and careful service.