With the popularity of charcoal products, people have started to demand higher quality and better performance of the final products. Therefore, the machine manufacturers are working on how to improve the machines to meet the customer’s requirements. The charcoal briquette-making line rises in response to the proper time and conditions. The charcoal briquette-making line conducts further procedures after the carbonization. The forming process can bring stable status and uniform shape to the final charcoal products, which can help the business owners earn more profits from the charcoal products. Learn more about the charcoal forming line, and start your own business with Sunrise Machinery Company.

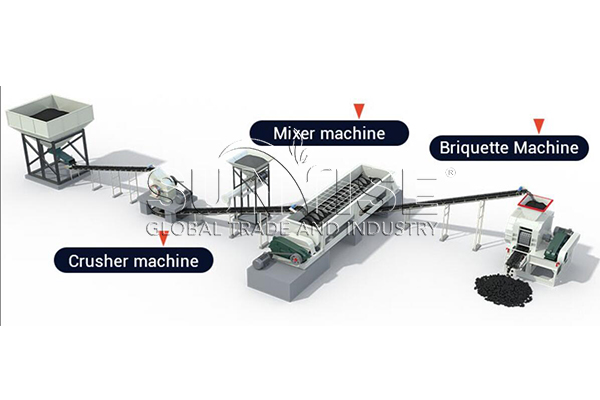

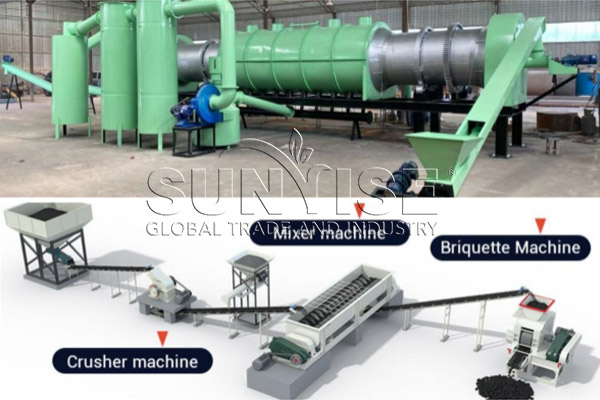

What machines does the charcoal briquette forming line compose?

There are several machines are the key components of the briquette forming line. The milling machine, the press machine, and the packing machine are the keys to making sure the customers can have a deep impression of the brand. That is to say, the business owner should purchase the equipment from a trustworthy manufacturer. Sunrise Machinery Company, the company can provides professional knowledge and careful service, is the choice that you should not miss.

Milling machines

The main purpose of the milling machine is to break down the charcoal bulk that came out of the charcoal carbonization furnace. The two most common milling machines are the edge runner machine and the Raymond mill machine. The edge runner mill usually has one or more pairs of rotating wheels, which are connected to the main structure through the axle. The shape and material of the wheel will vary according to the hardness and requirements of the grinding material. As for the Raymond mill machine, Raymond mills usually have one or more pairs of rotating rolls and fixed grinding rings. The material is friction and grinding between the grinding roller and the grinding ring to achieve the grinding effect. The Raymond mill transmits the material to the grinding stone through the air duct system for grinding, and the ground material is sent out of the equipment through the fan.

Forming machines

Since the customers have different requirements for the shapes of the final products, the machine manufacturers innovate different machines to produce different shapes. The two most common shapes of charcoal products are the ball and briquette. The roller press machine is designed to produce charcoal. With the compression of the two rollers, the charcoal powder can get into the shape of the molds. As for the charcoal briquette and cube, the impact-forming machine is the perfect choice. What’s more, the machine adopts the hydraulic system to form the charcoal briquettes. Therefore, the customers can choose the machine they want to realize the final outputs.

Packing machine

The package of the commodities is the first impression of the customer. Therefore, it is important to create a special package bag for the customers to remember the brand. In this way, the customers can become the regular customers. The packing machine can be designed as the customers require. The unique package bag is also a good promotion for the brand. The customer can also decide whether to purchase the machine or not.

How does the machines cooperate to form the charcoal?

In order to put out the best performance of the charcoal briquette making line, cooperation between the machines is extremely important. Normally, the whole working process of the charcoal forming line can be divided into three phases.

Why does the charcoal briquette making line is necessary?

People would wonder why it is necessary for a charcoal production line to have a forming line. There are many advantages to a compressed charcoal product.

What is the price range of the the charcoal forming line?

Normally, for a medium-sized charcoal forming line, the budget range should be set between $20,000-$50,000 (For reference only). The forming line usually contains with milling machine, briquetting machine, and packing machine. Of course, the machine set can have different options according to the requirements of the customers. The price can also have some differences.

Sunrise Machinery Company is a machine supplier with many years of experience. What’s more, the manufacturer has its factory to deal with the demands of the customers. The customers can get the most professional and careful service to start a new business. If you are interested in our charcoal machines or charcoal lines, please feel free to contact us.