A roller press briquetting machine is an equipment that produces different kinds of solid spheres from various types of powder. Charcoal powder is one of the raw materials for the roller press briquetting machine. The double roller presses the powder together to produce the charcoal briquettes. In the pellet shape, the charcoal can become more efficient. Due to the different scales of the production line, the customer can choose the suitable roller press machine to fit the productivity.

What parts compose the roller press briquetting machine?

To reach the goal of pressing the charcoal powder into a briquette, the roller press briquette machine only needs a few significant units. Different types of roller press machines may contain different parts or units, but all of them have a similar structure and working theory.

How does the roller press briquetting machine work?

The main part of the roller press briquette machine is the double-roller pressing part. The pressure-providing system plays a huge part in this process as well. With a series of operations, the roller press machine can bring the perfect charcoal briquette. The piston provides pressure from the action of the oil cylinder. The hydraulic pressure station offers the hydraulic oil to the oil cylinder through the pipeline, so the machine can maintain the high pressure for the roller’s pressing part. It is a necessary part of the charcoal production line.

Through the inlet, the charcoal powder falls into the gap between the two rollers. With the assistance of the pressure system, the two rollers squeeze the powder under extremely high pressure, so the powder becomes a solid charcoal briquette in the end. The surface of the roller usually has grooves or pits, which can form the charcoal into different shapes and add various decorative lines to the briquettes.

What are the advantages of the products of roller press briquetting machine?

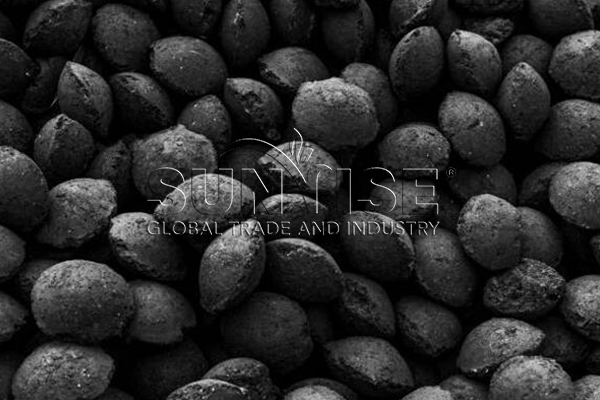

The pellet and briquette are the two shapes that the roller press briquetting machine can produce. Both of the shapes are the most classic forms for the charcoal press. But what advantages do these two shapes have to win people’s preference for them?

3 Charcoal Pellet Prominent qualities

The first merit of the charcoal ball is its high combustion efficiency. Due to the high standard of the roller press machine, the form of a ball can provide a larger surface for the charcoal to contact with the air. Therefore, the efficiency of combustion can be higher than other forms.

What’s more, the stability of combustion is something that improves the quality of charcoal. During the process of combustion, the center part of the charcoal pellet starts to burn in the first place, and it forms a burning core. The high-standard machine can produce higher quality final products on the production line to raise the reputation of the brand.

Last but not least, the charcoal ball is easier to transport and stockpile. The regular and compact shape gives the charcoal ball the ability to stick tightly to save the place. In this way, less damage can reduce unnecessary damage to help the customer to earn more profits.

3 Charcoal Briquette Excellent Characteristics

The first advantage of the charcoal briquette is the tight structure. The charcoal briquette is usually more dense than the charcoal pellet so that the combustion can extend longer and provide persistent heat.

The processed charcoal briquettes contain a stable status, and the stronger anti-pressure ability is one of the features as well. It leads to less damage to the charcoal during transportation and storage. The durability of the final products can give the customer a good impression for further purchase of the charcoal briquette.

The charcoal briquette is appropriate for many different types of combustion equipment with this classic and easy shape. When the charcoal briquette needs to get in or out of the heating equipment, the figure empowers it with the convenience of movement. Since the charcoal can fit most heating equipment, a great number of people can use the charcoal to help the customer gain more benefits.

Is the roller press machine necessary for the production line?

In the whole process of the charcoal production line, every piece of equipment plays a special role in producing the eligible charcoal products. But how come the roller press briquetting machine becomes a necessary part? The following features may answer this question.

How to choose the suitable roller press briquetting machine ?

With all the introduction above, it is important to learn how to choose the suitable machine to start a new business as well. There are several factors that you should pay more attention to on the machine of Sunrise.

All in all, the roller press briquetting machine is an important part of the charcoal production line. Besides the roller press machine, there are many other kinds of shaping machines. For instance, the extruder machine, the rotary press machine, and the shisha charcoal machine. The customers can choose Gradually, customers have a higher demand for the final product of charcoal, so a trustworthy manufacturer is what the beginner in this industry needs. Sunrise is the perfect choice for people who want to get into this business. With high quality and suitable price, the customer can have a wonderful experience in purchasing. Please leave your information if you would like to get more details.