The rotary tablet press machine is one of the most popular press machines. Besides the charcoal briquette pressing, many other industries can apply this machine as a forming machine. This machine uses the rotary system to press the material to produce products. With its unique mode of pressing and discharge, it can bring many benefits to the factory. Since many fields can use the rotary press machine, the development of the rotary press machine is following the needs of the state of the art.

What is a rotary tablet press machine?

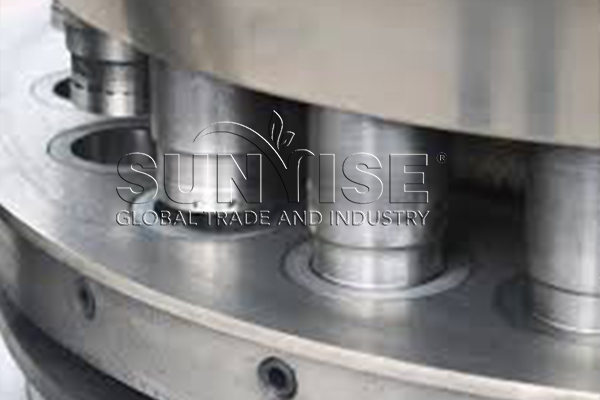

The rotary press machine has a broad base of use. It uses rotary motion to press the powder material together or in the shape of demands. Although the pressing system is the most important part of the machine, other parts make the rotary tablet press machine functional.

How does the rotary tablet press machine work?

To have a clear view of how a rotary tablet press machine works, two aspects need to be known. One aspect is the process of charcoal pressing, the other is the working principle of the press machine.

Process of Rotary Tablet Press Machine

To start with the process of pressing, the charcoal powder adds to the gap between the upper and lower molds. Then the motor and moderator come into play to provide the power to assist the molds to rotate. At the same time, the pressure system is also ready to bring the pressure to the molds to press the powder material. When the mold gradually compresses the charcoal powder, the production of the charcoal briquette is close to the end. The briquette still needs to be under pressure for a while to ensure density and strength. After finishing the whole press of the charcoal briquette making, the charcoal briquette can become the shape and size that the customers require.

Working Principle of Rotary Tablet Press Machine

By the effect of rotation and pressure, a charcoal powder can become a charcoal briquette with high density and strength. The size, shape, and surface of the charcoal briquette depend on the mold of the machine. Therefore, most manufacturers can customize the mold according to the requirements of the customers. Meanwhile, the synergistic effect of the hydraulic pressure system and the rotary system is the key to the rotary tablet press machine as well.

What are the advantages of the rotary tablet press machine?

There are many types of press machines in the market. The rotary tablet press machine can gain such huge interest from people mostly because of the following factors.

What other fields can the rotary tablet press machine come into play?

Since the rotary tablet press machine can deal with many kinds of powder, so the tablet machine can be useful in many industries. Making the powder into a tablet can enhance the stability and strength of the product. In this situation of charcoal pressing, these traits are important for industries with high standards.

Pharmaceutical Industry

The rotary tablet press machine has a wide application in the industry of pharmaceutical for making medicine tablets. Due to the tablet machine being able to bring out products with stable features and does, the pharmaceutical industry takes the machine into wide use.

Food Industry

Since the mold of the rotary press machine can have various forms, it is a perfect machine to create different types of snacks. The press machine can use to compress candy, chocolate, biscuits, and so on. The press machine brings the raw-food material together more tightly to increase the hardness and stability of the snacks.

The technology development trend of the rotary tablet press machine

The wide usage of the rotary press machine ensures its rapid development of it. Sunrise Machinery is devoted to producing machines that can comply with the latest trend of technological development.

The rotary tablet press machine has played an important part in the charcoal production line. The machine also brings more value to the final products. That is to say, the equipment can help the owner earn more benefits. If you would like to learn more details about the charcoal production line, please feel free to contact us by the inquiry button.