Now that the growing enhancement of environmental concepts, more and more people have started to realize the importance of energy-saving and recycling. The charcoal production line is the most popular machinery set for producing green energy from recycling materials. The charcoal production line for sale can attract more people to care for the green development. There are only several machines to contribute to the production line, and the raw materials are also easy to access. As the matter of the fact, the charcoal production line went through many years of development to evolve into the present version. Therefore, the future of the charcoal production line is promising because of its mass demand for the final products and environment friendly of the process.

What is the charcoal production line?

The charcoal-making line aims to produce high-quality charcoal products to earn more profits. The main working principle of the charcoal production line is carbonization. It refers to the chemical reaction process that breaks down carbon-containing raw materials into carbon and gas at high temperatures. Given that, charcoal production lines play an important role in industrial production and can efficiently convert carbon-containing raw materials into carbonized products to meet the needs of different industries. For the design and operation state of the charcoal products, the production line has a direct impact on the quality and output of the product, so it is necessary to carry out scientific and reasonable design and management.

In order to have a better understanding of the production line, there are many standards to classify the charcoal production lines. Raw materials, capacities, output, and parameters can all become the factors to separate the types of production lines. The customers can benefit from the classification to look for the charcoal machine line that is suitable for them. The popularity of the biomass charcoal machine lines is a good sign of green energy becoming the renewable source that the manufacturers would choose.

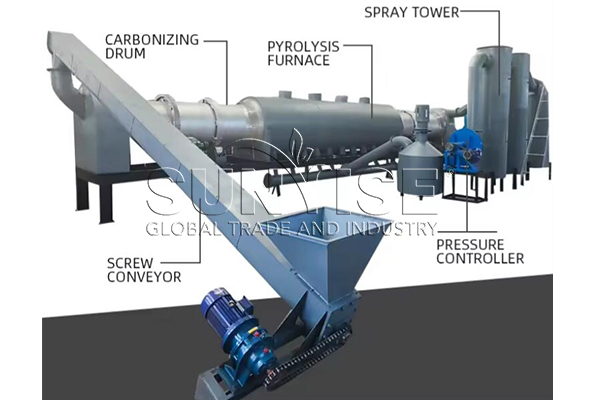

What composes the industrial charcoal production line?

What materials can biomass charcoal processing deal with?

The resources of the raw materials can be wide. Most business owners choose biomass materials or agricultural waste materials to produce charcoal products. Due to the charcoal machine line can deal with most kinds of biomass materials, the wide choices can bring continuous income for the business owners.

Biomass Materials

Most biomass materials are the stems of the plants, such as wood, bamboo, strew, and other kinds of plants. These plant-based feedstocks usually have high carbon content and low ash content and are suitable for the production of biochar. Especially, the turnover of the mature plants can ensure constant income from the charcoal machine production line.

Agricultural Waste Materials

The other huge parts of the raw materials of the charcoal production line are the agricultural waste materials, such as the coconut kernel shell, rice husk, and other wastes of food processing. These crop wastes can be converted into biomass carbon through carbonization, not only solving the resources of biomass charcoal but also helping to reduce the pressure on agricultural waste disposal.

What is the technique trend of the charcoal production line?

To offer a better user experience, the manufacturers of the charcoal production line keep improving the quality of the production line. During the development of the charcoal production line, there are several directions that the manufacturers constantly follow. The aspects can present the upgrade of the machines in the production line.

Automation and Intelligence

Advanced technology, amazing produtsFor the purpose of addressing the increase in demand for carbonized materials, the carbonized production line also tends to scale and integrate. Production scale can improve production capacity to meet the needs of the customers. The combination can integrate multiple production links, and improve production efficiency and product quality.

Production Scale and Integration

Better arrangement, higher efficiencyWith the increase in demand for carbonized materials, the carbonized production line also tends to scale and integrate. Production scale can improve production capacity to meet the needs of the customers. For this reason, the combination is a perfect solution for it can integrate multiple production links, and improve production efficiency and product quality.

Introduction of New Materials and Processes

New technique brings better qualityMeanwhile, the continuous progress of science and technology, new types of carbonized materials, and new processes continue to emerge. Hence, carbonization production lines need to constantly introduce and adapt these new materials and new processes to meet the needs of the market.

What is the price of the charcoal production?

The discussion of the price of the charcoal production machine is inevitable. The price of a product can be affected by many factors, which the customer should have a clear view of. Normally, the price range of the charcoal production line is $20,000-60,000. The number might change with the requests of the customers.

Sunrise Machinery company has a lot of experience in customization. The customers can get professional help and advice from the company. Besides, the company can design the best solution for the charcoal production line according to the space of the factory of the customers. If you would like to learn more about the charcoal production line or another charcoal-making machine, please leave your request. The professional service staff will bring the knowledge that you would like to as soon as possible.