The barbecue briquette making machine line provides the fuel to handle the food. As people pursue the delicious flavor of the food, barbecue charcoal production line has become inevitable. Therefore, more and more business owners notice the production line due to its promising future, high efficiency, and stable performance. With the working principle of carbonization and hydraulic pressure, the production line has a lot of options to form barbecue charcoal. Therefore, the production line combines the best outcome of machines and the labor inspection to ensure the quality of the final product.

What is a barbecue briquette making machine line?

The main purpose of the barbecue charcoal machine line is to produce the fuel for grilling the food. With the improvement of the living level of people, the basic flavor and safety cannot satisfy the people. The means of barbecue rise in response to the proper time and conditions. Through a series of processing steps, the raw materials become barbecue charcoal and burn to make delicious charcoal grilled food.

Nevertheless, the charcoal production line can do so much more. Biomass charcoal is not only the fuel for cooking, but also the energy that the charcoal can provide is enough to use as green energy in the industrial business. The charcoal-making machine line is one of the most important lines in the present energy production industry, which will play a significant role in future development. The improvement of the barbecue briquette making machine line promotes the whole industry to develop in a more healthy, environmentally friendly, and efficient direction.

What is a barbecue briquette making machine line?

For the smoke of the burning barbecue, charcoal can directly into contact with the food, the raw materials of the charcoal have to be harmless and safe to people. Therefore, biomass and agricultural waste materials are perfect for the production line. The process of the whole machine can be summarized into three parts.

What manufacturing techniques are used in the barbecue briquette making machine line?

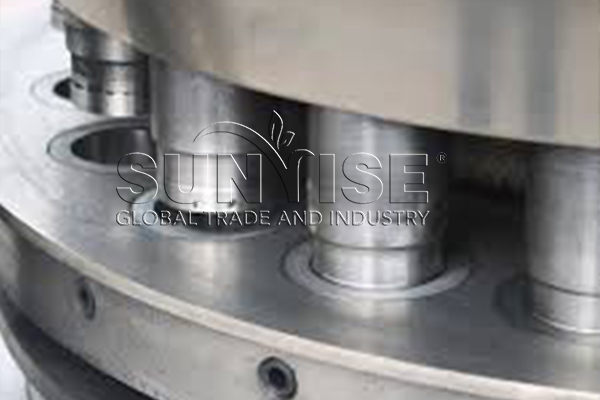

Compared to the traditional method, the conversion of the raw material becoming charcoal briquettes utilizes the technique of the machines. Every machine plays its part in the production line to produce high-quality products. The two most outstanding working principles are carbonization and hydraulic pressing.

Carbonization

As the core of the barbecue charcoal production line, most machines aim to assist in the completion of the carbonization process. Carbonization is a chemical process in which organic matter heats up at high temperatures under conditions of lack of oxygen. As a result, causing the materials to decompose into carbon and gases. In the process of carbonization, carbon elements in the organic material are left behind, forming a carbonaceous residue. The carbonization furnace of the Sunrise company can bear the heat of carbonization and provide a suitable environment for the materials.

Hydraulic Pressure

In the charcoal production line, the hydraulic system is also necessary. For the large raw materials like wood and bamboo, the hydraulic system contains the strength of crushing the materials into the suitable debris for the further process. As for the charcoal products after the conversion, the hydraulic system helps the refinement of the final products to meet the high standards for barbecue charcoal briquettes.

How does the Sunrise’s barbecue charcoal line maintain the quality?

The first thing to remember is that the most important thing about the barbecue briquette making machine line is the quality of the final products. The customers of the barbecue charcoal briquettes have an extremely high demand for the barbecue charcoal. Sunrise Machinery Company figures out several ways to help the operator maintain the quality of the charcoal briquettes.

Raw Materials Preparation

Raw materials preparation is necessarySince the materials of the barbecue charcoal line are mostly from the waste materials of agricultural processing, the preparation and processing of the raw materials are necessary. The removal of impurities and moisture can help to improve the quality of the final products. The crushing process accelerates the efficiency of the production line.

Mechanical Settings

Accurate parameters worth attentionOne of the advantages of the barbecue charcoal line is the automation level, and It is important to make full use of it during the production process. The operator can set the parameters of the machines as the customer requires. A fully automatic barbecue production line can maintain the high quality to win the brand a better reputation.

Manual Inspecation

Check the final products repeatedlyAt the end of the barbecue charcoal production line, an operator is necessary. For instance, the process of carbonization needs to be monitored, and more importantly, to inspect the basic status of the final products. After the briquette pressing machine, there might be some unqualified products in the batch, the operator needs to pick it out. What’s more, the end of the production line should also have a worker to check the appearance of wrapped products to ensure a good impression of the final products.

How much does a barbecue briquette making machine Line cost?

Many factors that can influence the price of the barbecue production line. Since the final products take part in the catering industry, the restriction may also affect the barbecue production line. The normal price of the production line is between $20, 000 to $50, 000. Certainly, if the customers have some special requirements for the barbecue production line, Sunrise Machinery Company can try their best to implement in the machines, but the price of the machine may experience a boost according to the adjustment.

With so many successful cases, Sunrise Machinery Company owns a relatively good reputation. Business owners need to have a trustworthy manufacturer. Above all, Sunrise is a perfect choice. If you have an interest in the machines and production lines, please send your inquiry to obtain more detailed information about the wonderful machines. The professional customer service staff will contact you as soon as possible.