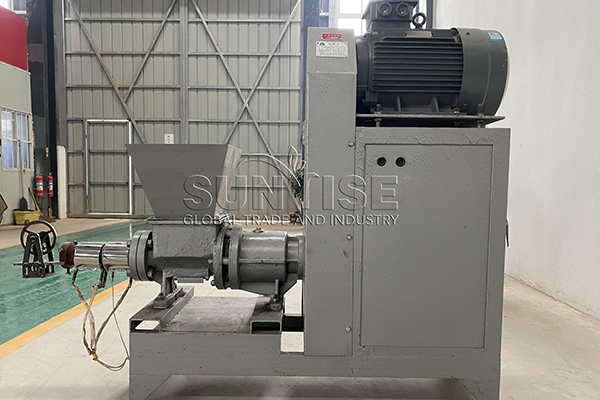

The charcoal briquette extruder machine is one of the most common forming machines in the charcoal production line. The high pressure and rotary screw of this machine assist in forming the product of the raw material. After the charcoal passes through the machine, the final product gains more added value than the raw material. Therefore, the charcoal briquette extruder machine plays an important role in transforming the charcoal into marketable merchandise.

How does the charcoal stick make by the charcoal briquette extruder machine?

To have a better understanding of the value of the charcoal briquette extruder machine, it is necessary to have a clear view of the extruding process. From the carbonation furnace, the process of making charcoal sticks contains the following steps.

What is the structure of the charcoal briquette extruder machine?

The charcoal briquette extruder machine contains several parts to make sure the machine can work smoothly.

Feed System

In order to process the huge amount of raw material, a good feeding system is what the customer should care about. Usually, the conveyor belt and square hopper inlet compose the feed system. The size of the feed port should adjust according to the scale of the whole carbonization charcoal production line.

Motor System

The most important part of the charcoal briquette extruder machine is the extruding part. The motor drives the extruding units to treat the charcoal stick. The motor-driven system provides energy and function of the extruding machine.

Shaping System

The extruding units push the charcoal powder forward to fit in the discharge hole. Therefore, when the customer has any specific requirements for the shape of the final product, the operator can use the mold to achieve the goal. The machine manufacturers can customize all the sizes, shapes and lengths according to the requirements of the customers.

How dose the charcoal briquette extruder machine work?

The working principle of the charcoal briquette extruder machine is easy to understand. Like other shaping and briquette machines, the pressure is the power to make all the magic happen. The motor and hydraulic system are the main sources of the high pressure. Both of the systems transfer the force from the machine unit to the material, so that the charcoal material gets out of the outlet to become the suitable appearance.

Besides the charcoal powder, sawdust, coconut shell, rice husk, and so on are the perfect materials to produce sticks as well. However, unlike charcoal powder, all these materials are going to process carbonization after the shaping stage. After the stick-making step, they have to experience drying and carbonization to become qualified charcoal sticks. As for the charcoal powder, the briquette extruding machine is the final step for shaping. In this way, the customer can take many kinds of materials into use to produce the charcoal stick.

The importance of using the charcoal briquette extruding machine

Some may wonder why the charcoal briquette extruder machine is so important in the charcoal-making process. For a factory of charcoal making, the regular shape may add more value to the charcoal final products. Sunrise machinery of charcoal briquette machine is the perfect choice for you to produce high quality charcoal stick.

Unique features of the final Product of the charcoal briquette extruding machine

There are many shapes for charcoal, so what are the advantages of the charcoal stick? After the usage of the Sunrise charcoal briquette extruding machine, what changes will happen to the charcoal stick?

High Hardness

After the charcoal powder goes through the extruding machine, the hardness of the charcoal stick enjoys a significant increase. The compressed charcoal stick has excellent abrasion resistance and high strength. These features give the charcoal the ability to maintain the same status after long-distance transporting.

Heat-Conducting Property

Since most of the charcoal sticks are used as fuel, it is important for the charcoal bar to have good heat-conducting property. During the process of charcoal briquette stick making, some manufacturers may add some combustion improver into the charcoal powder to make the final product more efficient for a kind of fuel. What’s more, the shape of a charcoal stick has a low coefficient of thermal expansion, so it maintains good stability in high-temperature environments.

Therefore, the charcoal briquette stick is one of those products with a promising future. The recycling of biomass is a popular trend for the development of future fuels. So if you would like to start your own charcoal processing business, please feel free to contact us.