With the development trend of environmental protection, the recycling of biomass matter is a subject that needs to be put on the development agenda. Wood pellet production line is the project that stands high in popular favor. The production line makes the wood raw materials into charcoal pellets to become useful again. To achieve the functional goal of the whole processing line, there are several machines to accomplish the working process and lift the production efficiency. As a great source, the wood needs to make full use of the materials and the recycling project can gain the raw materials at a lower price. Therefore, the wood charcoal production line fits the development trend and the benefit maximization.

What does a wood pellet production line do?

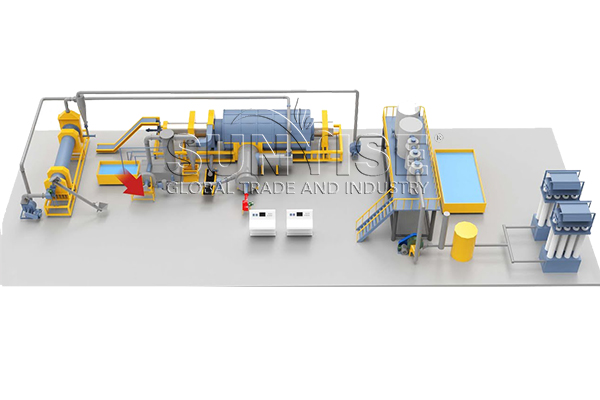

The main purpose of the pellet production line is to convert biomass raw materials into charcoal pellets. To achieve this transformation, the production line combines several machines to ensure smooth operation. Only with the precise process like the wood charcoal production line that Sunrise Machinery Company provided, the quality of the final products can be trusted.

The recycling of biomass matters is a great way to comply with the trend of environmental protection and energy conservation. As a renewable resource, the long regeneration period may influence the benefits, so the reuse of the waste material is an inevitable choice. The transformation from wasted materials to biomass energy is a useful way to reduce consumption and environmental impact. Therefore, it has significant meaning for sustainable development and environmental protection by using wood material as a renewable resource.

What composes the wood pellet production line?

The shredder machine, dryer machine, carbonization furnace, grinding machine, briquette machine, and packing machine combine the production line of wood charcoal. Each machine plays a unique role in the process to maintain the functioning performance of the processing line.

What advantages does wood have to become the raw material of the wood pellet production line?

Out of many kinds of materials, wood has always been the most popular choice of carbonization material. There are three main reasons why the wood material can have such wide application.

Natural Property

The reason why the process of carbonizing chooses wood as the raw material is because wood mainly consists of organic materials, which can decompose to produce carbon under high-temperature conditions. In the process of wood carbonization, the extra water and volatile substances are getting out of the wood raw material, and the carbon left will gradually increase. Only in this way, can the wood material become the final charcoal product.

Broad Sources

As a common resource and material, many industries use wood to improve the final products. So many waste wooden products that are suitable for recycling. The wood charcoal production line is a great chance to put the wooden products into use again. The resources of the wooden products are wide, so the supply of the raw material can be maintained at a continuous condition.

Low Cost

With the wide sources of the raw materials, the price of the wooden materials is rather low. Since wood materials are a renewable resource, which provides the stability and sustainability of the supply. Due to the wide application of wood, the market demand is large, and the production scale is relatively large. Mass production can reduce production costs, which makes the price of wood relatively low.

What economic benefits does the wood pellet production line contain?

Wood carbonization production line has become an investment choice with high economic return and potential. The concept of recycling wooden products can comply with the development trend of energy conservation. Therefore, the wood charcoal production line can bring abundant benefits to the owner.

High Value-added Products

Higher quality, higher priceWood carbonization production lines can convert wood into high-value-added carbonization products, such as wood activated carbon. These products are widely used in adsorption and filtration, water and air purification, energy storage, and other fields, and the market demand is large and the price is high, which can bring high profits.

Sustainable Development

Continuous development for better produtWood is a renewable resource, and the operation of wood carbonization production lines can realize the effective use of resources and sustainable development. This is in line with the requirements of environmental protection and sustainable development. What’s more, it can also obtain social recognition and support. The environment-friendly concept can provide a better reputation for the brand.

Market Potential

Demands decide directionCarbonization products are widely used in various fields, and the need for energy is large and growing. Wood carbonization production lines can produce a variety of different specifications and uses of products to meet market demand, with great market potential.

The price range of the wood pellet production line

The price range of a wood pellet production line can be wide. Many factors can influence the final price of the processing line. The normal price range of the wood charcoal production is between $10,000-$50,000. The biggest factor that affects the price is capacity. Lower capacity can be covered by smaller machines, and the prices of smaller machines are lower than the large-scale machines. Therefore, the customer should have a clear view of the conditions of the capacity.

Sunrise Machinery Company is a manufacturer with years of experience in machine-making. It can provide you with professional suggestions and designs for the factory. Since the manufacturer has a factory to produce the machines, the offer of the company is a reasonable price in the market. The machine can also be customized according to the demands of the customer. If the customer would like to learn more about the machines and production lines, please contact the company via E-mail. The customer service staff will answer the requirements as soon as possible.