How much does the roller press machine cost?

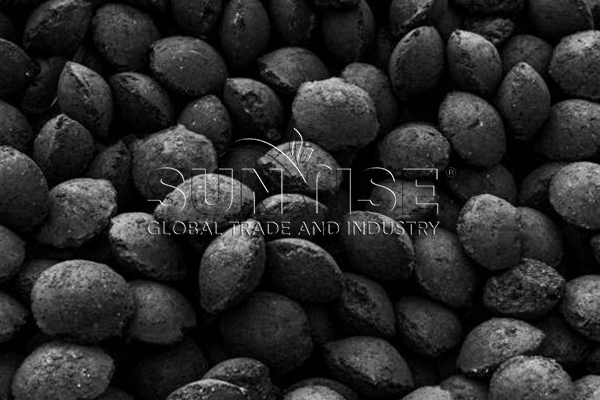

For a charcoal production line, the forming process is a very important process. For that reason, the utilization of shaping machines is also a subject that cannot be ignored. The general price of a double roller press machine is between $5,000-$10,000. There are various types of charcoal briquette machines for the customers to select. However, the factor that affects the decision of the customer the most is the price. Sunrise Machinery Company is a machine manufacturer with years of experience so the company can provide many different solutions for the customer. What’s more, customization is a perfect method to meet the demands.

Factors of the roller press machine price: capacity

There are many different factors may influence the price of the roller press machine. The first factor that has influence on the price is the capacity. The different speeds and sizes of the roller press machine may lead to different amount of the outcomes. The larger the production scale is, the higher the price is.

Factors of the price: quality

The next factor that may cause changes in the price is the quality. The prices of the roller press machines in the market can be quite different. One feature that affects the most is the quality of the machine. Due to its working principle, the machine’s structure is simple and useful, which means the parts need to overcome the high strength use. Therefore, it is important for the roller press machine to have durable parts in it to maintain the best performance of the machine and the quality of the final products.

Factors of the roller press machine price: customization

In addition, the customization can have a great impact on the price of the machine. Most customers choose the press machine as a part of the whole production line. Therefore, lots of the customers have their demands for the shape and quality of the machine to have different figures from other brands. Sunrise Machinery Company has the experience to deal with the requirements and offer professional advice. If you would like to start your own charcoal briquette business, please feel free to contact us.

Factors of the price: level of automation

Last but not least, the level of automation is also a significant factor to affect the price of the machine. In order to accelerate the speed of production, the roller press machine would normally be designed as a machine that is easy to operate. The price of the highly automatic machine can be higher. Highly automated machines usually have more automation functions and intelligent control systems, which can realize automated production processes, reduce human error, and improve production efficiency. The more automated the machine, the more sensors, control systems, automation components, and intelligent software, these additional technology and equipment costs increase the manufacturing cost of the machine.

As a highly automated and lower-budget machine, the double roller machine attracts many attention of the customers. Compared to the traditional and semi-automatic, the automatic roller press machine has higher production efficiency. The lower cost of labor can also reduce the cost of the production process. The roller press machine adopts the precision roller structure and pressure control system to maintain the quality of the final products. What’s more, the machine can change the rollers to alter the shape of the charcoal briquette. Roller press charcoal machine has the advantages of efficient production, high degree of automation, high precision, versatility, energy saving, and environmental protection, and is one of the commonly used equipments in the production of carbon material products.