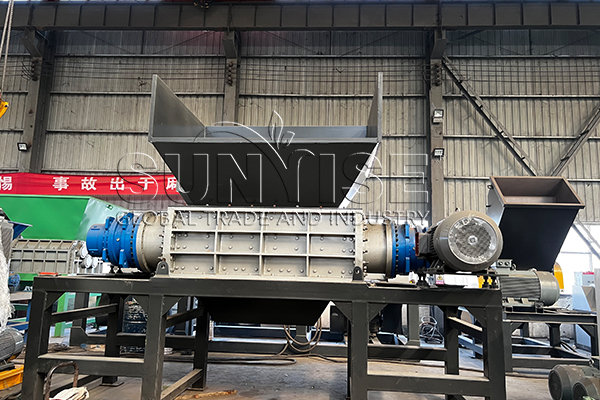

The double-shaft shredder machine is famous for its strong shredding power. The robust performance of this machine relies on the rollers, cutter head, and other machinery parts. When the materials get into the shredder machine, the blades will cut up the material into fragments, and the roller will press and tear the material into a suitable size. That is to say, the double-shaft shredder contains many advantages that make it the most competitive machine for dealing with raw materials.

What is a double-shaft shredder machine?

Many fields put the double shaft shredder machine into use to conduct treatment on the raw materials. On account of this, the machine can perform the shredding processing of the solid materials. When solid bulk materials become debris, the further steps of the production line can release more potential for use. The main function of this machine determines that it is the perfect machine for scrap metal recycling, waste plastic disposal, wood processing, and many other fields.

According to various metal characteristics and processing demands, the double-shaft shredder machine can alter the shape of the blades, the speed of the main rollers, the method of feeding, and many other parameters to reach the best shredding result. In practical use, the double shaft machine usually matches with other machines. In order to constitute a set of treatment lines to maximize the value of the materials.

What parts compose the double-shaft shredder?

A double-shaft machine consists of an inlet, two main rollers, blades, an outlet, and a control system to achieve smooth performance for working.

How does the two-shaft shredder machine work?

A series of physical changes realize the pre-process of shredding the materials. It is the beginning of the charcoal production line as well. The working process of the machine is to put the material in the double shaft shredder machine through the inlet, and the double-roller will crush and press them during the motion of rotation.

When the materials get into the shredder machine, the main rollers are starting to rotate. In this process, The blade on the spindle begins to rotate, and the material experiences cut, tear, and break, and gradually becomes smaller under the action of the blades. The shredded material discharges from the machine through the discharge port, which can be put into the process again for other purposes. The two-shaft shredder has the advantages of high shredding efficiency, large processing capacity, wide application range, and high degree of automation, and wide usage in the fields of waste material treatment and recycling of renewable resources.

What are the differences between the shaft shredder machine and double-shaft shredder machine?

When people talk about the shredder machine, it is inevitable to involve the comparison. The unique traits of the shaft shredder machine and the double shaft shredder machine make them suitable for different fields. There are several differences for the customer to choose the suitable machine.

What are the advantages of the double-shaft shredder machine?

Stronger Processing Ability

The two main rollers of the double shaft machine can rotate simultaneously. It can effectively improve the efficiency and speed of material processing. For this reason, the equipment can quickly shred waste materials into smaller pieces, reducing the workload of subsequent processing.

Wider Range of Processing

The dual shaft shredder is suitable for handling various shapes and hardness of waste materials. The list of raw materials includes metal, plastic, wood, palm kernel shells, rice husk, and so on. However, different types of materials can enjoy different methods of handling. Changing the parameters of the rollers and blades enhances the quality of the final products.

The double-shaft shredder machine plays an important part in the field of recycling and waste treatment. With the function of the two-shaft shredder machine, the waster will cause less damage to the environment and boost the utilization rate of the materials. The price range of the double shaft machine is between $3,00-$20,000. Since the subjects of environmental protection and ecological conservation are on the trend, the double-shaft shredder machine will have a wider application in the market. If you would like to learn more about the machine, please feel free to contact us.